LSU Research Bites: This Innovative Recipe Turns Natural Wood into Safer Building Material

January 09, 2026

LSU researchers have a successful history of developing higher-performance and more sustainable materials, including wood-based composites.

Why create new wood materials? Because, despite Louisiana’s rich forest resources and our widespread use of wood to build our homes and other structures, wood has serious limitations: it is susceptible to fire and biological deterioration.

While some wood treatments exist—for example, chemical treatments that protect against termites—these treatments often only address a single hazard. They don’t protect against both fire and biological risks simultaneously, for example.

They also often involve chemicals that are concerning for environmental or human health, and are difficult or costly to apply.

“We need an integrated, multifunctional wood modification strategy that combines structural reinforcement with multihazard protection,” says Qinglin Wu, Cain Chair and Roy O. Martin Sr. Professor in the LSU AgCenter School of Renewable Natural Resources.

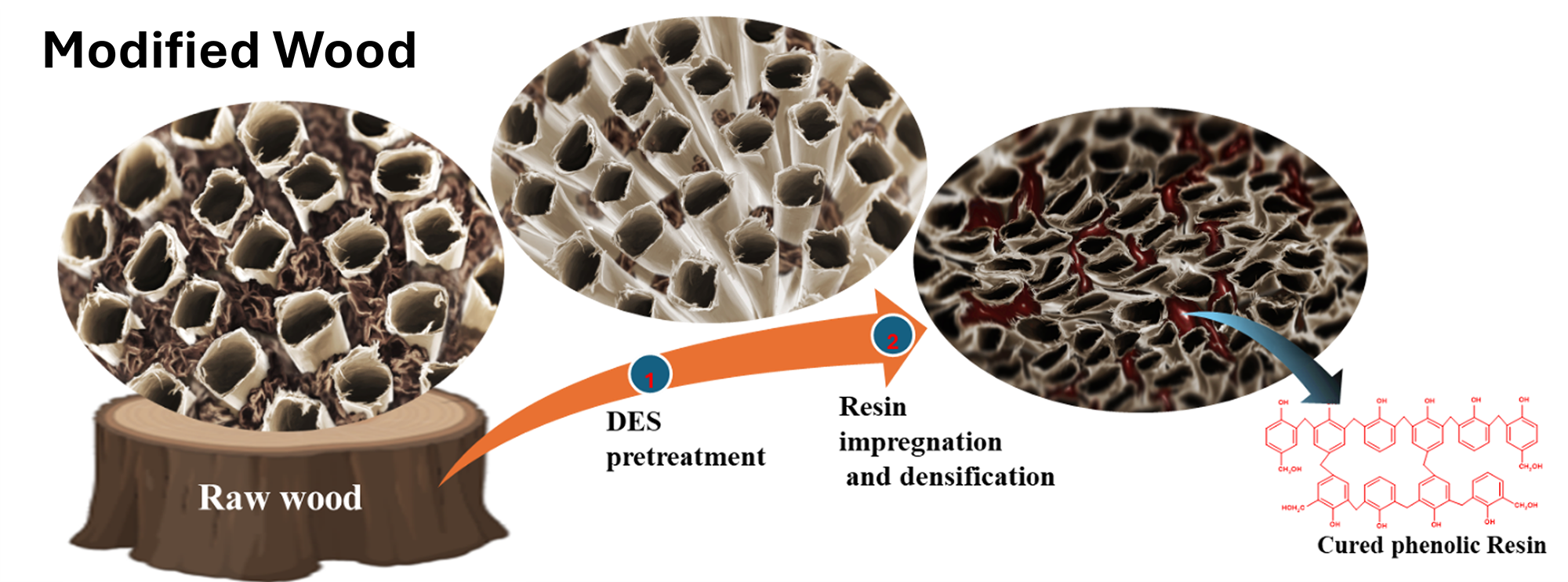

Wu’s lab has developed a new process to improve natural wood by combining physical and chemical treatments. First, they treat wood to increase its strength, and then they infuse it with chemicals for fire resistance and termite protection.

The newly created wood material exhibits significantly improved strength and enhanced fire resistance.

Wu lab recipe for more resilient wood

- Chemically remove lignin, a component of wood that makes it rigid, so the wood has more room for chemical treatment compounds and can later be compressed and strengthened

- Treat the wood with a phosphorus-containing flame retardant, a “greener” alternative to older and more toxic options

- Treat wood for termite protection with the borate-based compound DOT, which is water-soluble and non-toxic to humans.

- Compress the wood with pressure and heat to increase its density

A cool fact about steps two and three of this “recipe” is that they involve a "dual-phase" protective mechanism. The flame retardant, APGP, is a foam that works by creating a puffy layer that, if touched by fire, forms a blackened and tough “char” that blocks heat and insulates the wood from further burning.

The next chemical, DOT, forms a barrier that prevents oxygen from reaching the wood, effectively starving any fire and providing termite protection simultaneously.

This recipe “could significantly benefit the state's wood industry by developing high-value products from Southern pine and other local wood species,” Wu says.

This innovation not only increases the market value of the state's forest products but also helps mitigate risks from threats like wildfires, supporting long-term sustainability and economic growth.

Read the paper: Structural and Chemical Modification of Cellular Wood Composite for Enhanced Strength, Fire, and Biological Resistance

Next Step

Discover stories showcasing LSU’s academic excellence, innovation, culture, and impact across Louisiana.